MOULDING INSERTS FOR PLASTIC

INJECTION MOULDING INDUSTRY

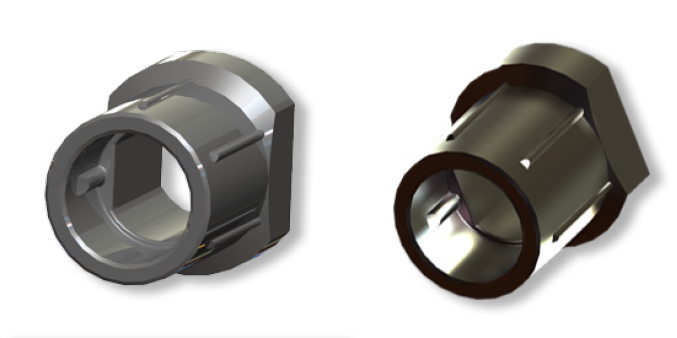

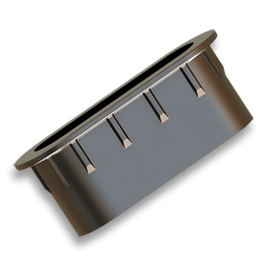

Our range of sintered metal compression inserts have features to resist axial and radial forces. We can also design a feature that will eliminate any over-moulding on the end faces. Furthermore we can also incorporate an anti-rotation feature such as a spline or hexagon to ensure optimum efficiency in the finished limiter.

Our compression limiters are designed to ensure the stability and integrity of the bolted connections. The limiter absorbs the required pressure without compromising the make-up of any other materials in your assembly. Whatever your application, we can supply a suitable compression limiter.

GTB Components Ltd also manufacture a full range of sintered moulding inserts used by the plastic moulding industry.

We strive to produce only the finest powder metal moulding insert, manufactured in a process that is cost-efficient and yields high-quality reliable results.

Our inserts can be inserted in a number of different ways. For example, they can be incorporated during the moulding process or any time after the process if finished. If you choose to add them during the moulding process, this can be done via robot assistance or by the process operator.

There are many applications of our moulding inserts and they can be used in any of the following processes:

Sintered Compression Limiters

• Injection Moulding

• Compression Moulding

• SMC / DMC Moulding

• Rotational Moulding

• GRP Moulding

• Extrusion Blow Moulding