The intensifying electrification trend in the automotive industry along with calls for high-efficiency, low-cost industrial applications will drive the demand for energy- and cost-efficient electromagnetic components. Soft Magnetic Composite (SMC) materials play a fundamental role in this conversion, making it possible to manufacture more compact and cost-efficient motor and inductor solutions compared to using traditional designs.

The main benefits of SMC solutions for both motor design and production processes are:

• Compact design – both size and weight of the components can be reduced

• High performance – can meet the highest efficiency requirements

• Excellent cost efficiency – the compact designs require less material and enable simple net shaping production process with minimum waste and reduced need for subsequent operations.

Our Soft Magnetic Composites can be used in a wide range of different applications such as:

SMC (Soft Magnetic Composite) V Traditional Laminated Steel

The traditional lamination (electrical) steel motor construction is being challenged by the emergence of powder metal parts made from soft magnetic composite.

Magnetism: Soft Magnetic Composite Vs. Laminated Steel

Magnetic properties depend strongly on the manufacturing process.

For laminations, the manufacturing process can include:

- Punching

- Stacking

- Welding

- Riveting

- Pressing

Each of the above processes deforms the interior of the material, resulting in weaker magnetic properties.

Because ferromagnetic materials (like SMCs) have a different structure, you’ll see a different distribution of magnetic losses in them.

For example, the hysteresis losses (energy wasted in by heat loss) in SMCs are higher, BUT, eddy current losses are much lower in soft magnetic composites. Their eddy losses are lower because the tiny composite particles are so isolated.

2D of Laminated Vs. 3D of SMC’s

Steel laminate motor construction is limited to 2D magnetic flux so you don’t lose too much magnetism in the direction perpendicular to the laminate.

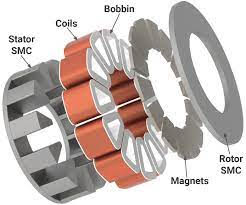

However. because soft magnetic powder composites create a 3D magnetic flux path, design options increase greatly.

SMC material’s makeup combined with its net shaping capability allow you to introduce new 3D solutions with minimal iron (magnetic) loss and optimized copper winding. Even a standard motor’s performance and capabilities can be upgraded through the design options presented by SMC .

Axial Flux Machines: save space, weight and Cost

The magnetic and net-shaping properties of SMC material and GTB Components powder metal production process combine to make SMC components a key enabler of axial flux machines.

The Challenge

Demand for compact, energy-efficient electromagnetic components is greater than ever before given the rise of electrification within the automotive industry. Enabling space-efficient designs for various motor applications, and low-cost manufacturing in large volume production, are crucial requirements.

The Solution

Axial Flux Permanent Magnet machines (AFM) help cater for this demand. They are very compact constructions with high power density. AFM’s typically larger diameter and shorter axial length makes them ideal for a number of automotive applications, including full electric or hybrid traction drives, electric auxiliary pumps and AC compressors.

It is the 3D magnetic properties and net-shaping capabilities power metallurgy and SMC based components used that open up opportunities to design compact solutions like axial flux machines.

GTB Components Ltd is especially tailored for high volume, cost-efficient component production by utilising the Powder Metallurgy (PM) forming process produced on GTB UK designed and manufactured high speed presses.

SMC components are ready to use after compaction and heat treatment and show close dimensional tolerances and robustness in large series production.

The Result

Why SMC materials for Axial Flux Machines? Because they are compact, cost-efficient and offer high performance based on:

- High power and torque density optimal design concepts at standard rpm

- Net-shaped 3D components

- Pre-wound slide-on and tightly wound coils at high fill factors

- A simple, automated assembly process with low investment

- High frequency operations at low losses

- Thermally isotropic Somaloy cores combined with dense coils enables optimal, efficient cooling

- A short axial length and small build-volume, which adds value when space is limited

- Reduced need for very high rpm gearboxes

Soft Magnetic Composite (SMC) Design Considerations

General Do’s and Don’ts

- Maximum surface area of 100cm2 recommended. If larger then segmenting may be considered

- Maximum part thickness of 4cm recommended so that density can be optimised to ensure best possible magnetic performance

- Minimum wall thickness of 2.5mm is suggested

- Avoid thin , sharp corners

- Radii can be added to take max advantage of net shape powder metal production process thereby improving magnetic and mechanical properties

Large Motor Design? Segmenting is possible with SMC parts

Segmenting SMC parts using glue allows large motor designs to be considered. Sizes never considered possible by powder metallurgy become a reality.

Automotive

- Traction motors

- Air conditioning compressors

- Pumps (cooling, oil, etc.)

- DC/DC converters

- On-vehicle chargers

Industrial

- Air conditioning compressors

- Ventilation fans

- Solar power

- Industrial motor drives

- Off-board battery charging

The SMC materials are developed for component manufacturing of electromagnetic applications, providing high performance and low losses. They are designed for efficient volume production at low cost, by utilising state-of-the-art technology. It is the 3D magnetic properties and the net shaping capabilities of the SMC materials that open up new opportunities to design compact, light and cost-efficient solutions.

Examples of how SMC materials can provide lower production costs:

- Size and weight reduction of components

- Reduction of the total number of parts in the final application

- Less need for machining

- Low scrap rate in manufacturing

Material Benefits:

- High resistivity

- High flux density

- Tight tolerances achievable

- Low core losses at High frequencies

- High permeability

- 3D flux paths

- Net shape capability