Gas Nitride treatment is a “low temperature” furnace treatment with an atmosphere of Ammonia. The Nitriding process is an established and successful means of generating a hard case on a component.

This process is most useful for components such as Crankshafts, Gears and a multitude of other parts in tough environments (especially oil & gas, energy, aerospace, etc).

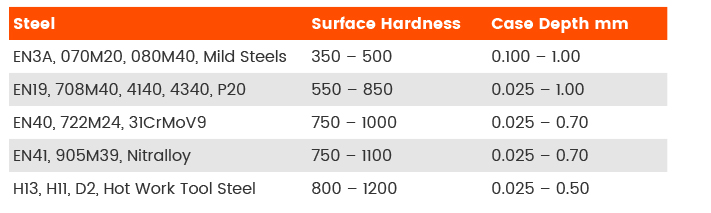

The following table are presented typical hardness and case depth for common nitrided steels:

The crucial benefits of the process are:

- Wear resistance: created by a diffused hard surface layer.

- Negligible dimensional changes.

- Improved fatigue properties: the process induces compressive stress, which improves fatigue strength.

- Improved corrosion.

- No reduction in the core hardness of the base metal.

Size Range:

- Max height: 1000 mm

- Diameter: 610mm

- Max Load: 1000 kg

Interested in nitrocarburizing & nitriding?

Fill out the form below and a member of our team will contact you

1